Seawater desalination is an important pathway to the sustainable supply of fresh water for our modern society. Recently, the invention of ultrafast seawater desalination membranes by scientists in China has become a trending topic. Tianjin University, collaborated by Nankai University and other three institutions have developed a new kind of membrane material, named covalent organic framework (COF), which exhibited high water permeation flux, high salt rejection and excellent fouling resistance. The relevant findings were just published in the journal Nature Sustainability.

The first author of this research article, Wang Meidi, a Ph.D. student at the School of Chemical Engineering and Technology, Tianjin University, had just passed his Ph. D thesis defense.

“I stayed for my research work during 2021 winter vacation. I felt energized and excited since our membranes had displayed desirable separation performance and we made full use of time to carry out more systematic and in-depth investigations.” Wang said.

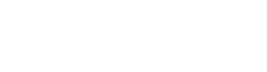

Illustration of three categories of seawater desalination technologies

Jiang Zhongyi, the leader of this research project, and a professor at the School of Chemical Engineering and Technology, Tianjin University, who have been engaged in biomimetic and bioinspired membrane research for over 20 years, said: “In our project, we adopted a new approach, the thermal-membrane coupled desalination technologies exemplified by pervaporation. So far, two main categories of seawater desalination technologies have been developed: thermal-based technologies, represented by multi-effect distillation and multi-stage flash evaporation, and membrane technologies, represented by reverse osmosis.” He added: “Thermal desalination is the first developed desalination technology, but it usually consumes a large amount of energy because water has to be evaporated into vapor and then condensed into water.With the advancement of membrane materials, reverse osmosis technology is developing rapidly, accounting for at least 80% of all newly established seawater desalination devices. We envisaged that whether we could combine the merits of these two technologies, thus we adopted an alternative membrane process--pervaporation.”

There are more than twenty kinds of desalination technologies around the world, and desalinated saltwater has even become the primary source of fresh water for many regions suffering from severe water shortage in the world. Desalinated seawater is also used in many coastal regions in China.

According to Professor Jiang Zhongyi, their project not only combines the benefits of thermal and membrane technologies, but the most significant innovation is material design. “In the past, seawater desalination usually uses the conventional polymeric materials, which are easily available and processable, but the desalination performance is relatively low. For instance, if the road straight, the car can drive very fast. However, if the road is tortuous, the car will drive slowly due to the much greater resistance. Now we employ a novel kind of material called covalent organic frameworks (COFs), which possess long-range ordered channels,” Professor Jiang added.

Illustration of the scale growth of the nationwide seawater desalination project

Sandcastle worms,Phragmatopoma californica, live along the western coast of North America. The worms build tubular shells under seawater by gluing together sand grains and biomineral particles with a multipart, rapid-set, self-initiating adhesive.

“We wondered whether we could find something to adhere the COF nanosheets (NS) inspired by this bionic strategy” said Professor Jiang: “Researchers from Nankai University provided us such adhesive—COF nanoribbons. We employed nanoribbons to adhere the COF NS, which made the COF NS grow larger and have superior when they were assembled into membranes. The permeation flux of our membranes surpassed the present polymeric membranes by four to ten times, outperforming the almost all the state-of-the-art designs”

Water scarcity is a major challenge for global sustainable development and billions of people lack access to safe fresh water. If seawater, which makes up more than 96 percent of the Earth’s total water capacity, can be transformed into fresh water, it is unquestionably a great solution to alleviate the shortage of fresh water resources.

“Desalinated saltwater used as drinking water is possible,” Professor Jiang Zhongyi said, “But for now, people still prefer to utilize groundwater, rainwater, and natural water if it can meet the drinking standard, while desalinated seawater needs first to meet our industrial requirements.It’s no longer a question of quality, but rather of price.”

Desalinated saltwater has a bright future, whether for industrial manufacture, or daily life, but only if the cost is further decreased while the quality and efficiency issues of large-scale production are resolved. This is the driving force behind Tianjin University’s and Nankai University’s joint research team. According to Zhang Zhenjie, professor at the College of Chemistry, Nankai University, the team is undertaking more extensive studies to put the scientific achievements into practical application as soon as possible.

“Our group is working on lowering the cost of the material, and we’ve been able to get it down to 0.1 RMB per gram, which is comparable to the cost of other commercial porous materials. The other issue is how to realize large-scale production. Professor Jiang Zhongyi and his group are working on it, and theoretically, scaling up is rather promising. As far as I know, the officials and experts from the Ministry of Science and Technology of China, as well as some enterprises, are very interested in our project and are working on the next steps to take this technology from the lab to the real applications.” Professor Zhang said.

A seawater desalination facility in Qingdao, Shandong province, China

By Zou Yu

Editors: School of Chemical Engineering and Technology, Sun Xiaofang